Food conveyors are an essential component in the food production and packaging industry. They transport food products from one stage of production to the next, minimizing the need for manual labor and improving overall efficiency. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

At Titan Industries, Inc., we excel in delivering comprehensive solutions for material handling through our innovative conveyor systems. We specialize in designing and manufacturing a diverse range of conveyors, tailored to meet the unique demands of various industries. Our product lineup includes modular belt conveyors, roller conveyors, and custom-engineered systems that cater to both standard...

At Benda Conveyor Solutions, we specialize in delivering advanced conveyor systems designed to elevate your operational efficiency. Our expertise spans a diverse range of industries, and we take pride in providing solutions that not only meet but exceed our clients' needs. Our comprehensive portfolio includes everything from modular conveyor systems to custom-built solutions tailored to specific...

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Food Conveyor Manufacturers

Components of Food Conveyors

A food conveyor is composed of several components that work together to transport food products along the production line. These components include:

The Belt

The belt is the most visible part of the conveyor system. It transports food products from one point to another along the production line.

Conveyor Rollers

Conveyor rollers support the belt and allow it to move smoothly along the conveyor.

The Drive Unit

The drive unit powers the conveyor belt and moves it along the production line.

The Tension Unit

The tension unit ensures that the belt is tight enough to prevent slippage and efficient operation.

The Support Structure

The support structure keeps the conveyor belt at the proper height and angle.

Variations in Components and Design of Food Conveyors

There are several variations in components and design of food conveyors. Some of these variations include:

Belt Type

There are several types of belts that can be used for food conveyors, including flat belts, modular belts, and timing belts. Each type of belt has unique characteristics that make it suitable for different applications.

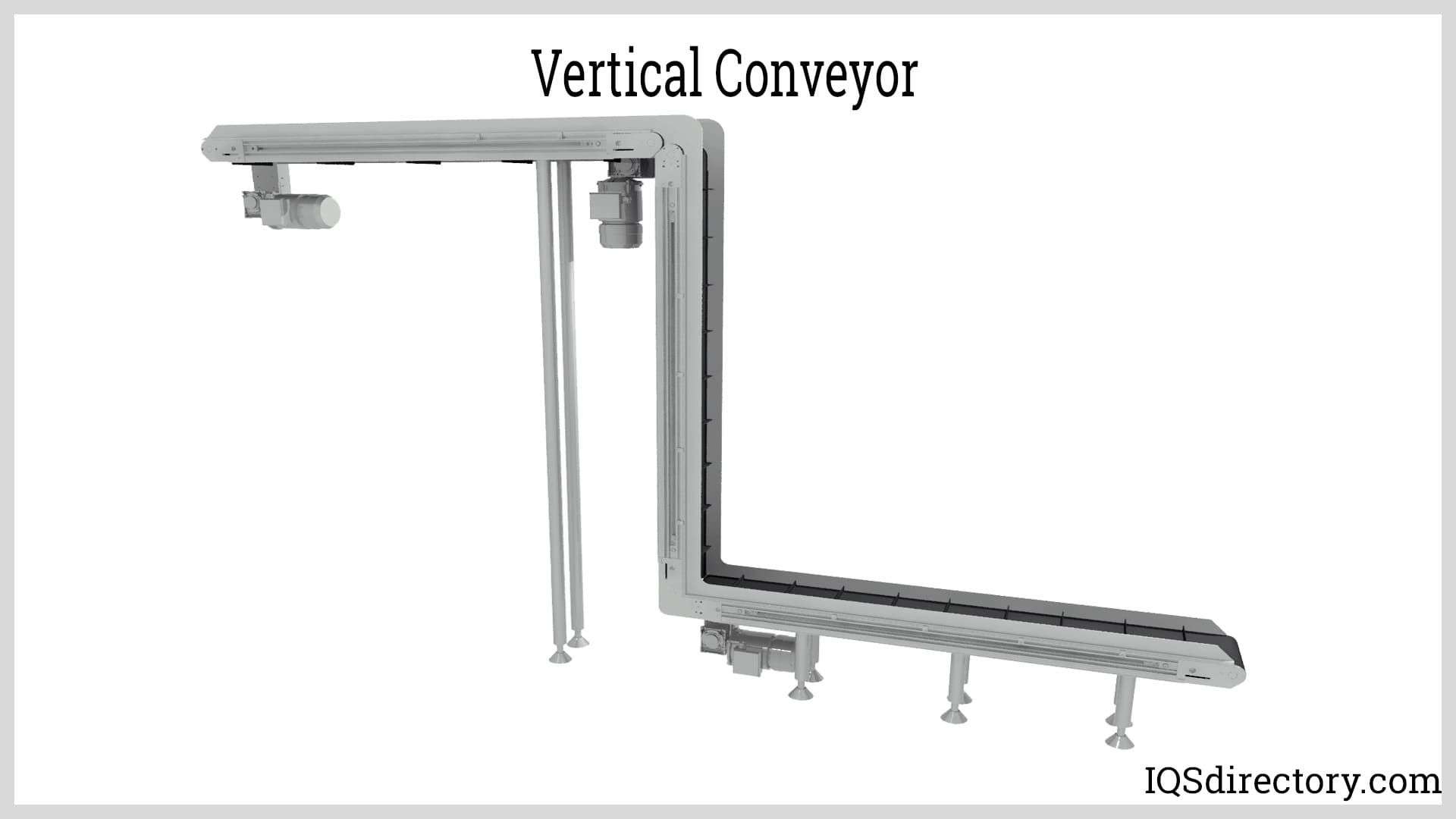

Conveyor Configuration

Food conveyors can be configured in several different ways, including straight, curved, incline, or decline configurations. The choice of configuration will depend on the layout of the production facility and the specific requirements of the application.

Conveyor Length

Food conveyors can be designed in various lengths depending on the requirements of the application. Longer conveyors may be necessary for large-scale production facilities, while shorter conveyors may be more suitable for smaller facilities.

Conveyor Speed

Conveyor speed can be adjusted to suit the requirements of the application. Faster speeds can increase production capacity, but may also increase the risk of product damage or spillage.

Conveyor Accessories

There are several accessories that can be added to food conveyors, including side rails and chutes. These accessories can help to ensure that products are transported safely and efficiently along the production line.

By understanding the different variations in components and design of food conveyors, food manufacturers can choose the best conveyor system for their specific application. This can help to improve efficiency, reduce costs, and enhance product quality and safety.

Materials Used as Food Conveyor Belts

As the component that transfers food in food conveying systems, it is important to consider the materials which may be used as food conveyor belts. Below is a list of many materials used as food conveyor belts, along with the beneficial qualities they possess for this application.

PVC

PVC (polyvinyl chloride) is a synthetic plastic material that is commonly used as a food conveyor belt due to its low cost, durability, and resistance to oil and chemicals. PVC belts are suitable for transporting products that are dry or contain minimal moisture.

PU

PU (polyurethane) is a synthetic material that is commonly used as a food conveyor belt due to its high resistance to abrasion, oil, and chemicals. PU belts are suitable for transporting products that are moist or oily.

Rubber

Rubber is a natural or synthetic material that is commonly used as a food conveyor belt due to its resistance to abrasion, chemicals, and high temperatures. Rubber belts can be designed with various textures and patterns to provide grip and reduce product slippage during transport.

Stainless Steel

Stainless steel is a metal that is commonly used as a food conveyor belt due to its high resistance to corrosion and its ability to withstand high temperatures. Stainless steel belts are suitable for transporting products that are hot or require high levels of hygiene.

Teflon™

Teflon™ is a synthetic material that is commonly used as a food conveyor belt due to its high resistance to heat, chemicals, and corrosion. Teflon™ belts are suitable for transporting products that are hot or require high levels of hygiene.

Cotton

Cotton is a natural material that is commonly used as a food conveyor belt due to its high resistance to abrasion and its ability to absorb moisture. Cotton belts are suitable for transporting products that are moist or require high levels of hygiene.

In general, food conveyor belts must be made from materials that are safe for use with food products, and that can withstand the harsh conditions of food production facilities. Food-grade conveyor belts that meet FDA and USDA regulations should be used to ensure that food products are not contaminated during transport.

Types of Food Products Transported on Food Conveyors

Food conveyors can transport a wide range of food products, including raw ingredients, processed foods, and packaged products. Some foods, such as liquids or sticky substances, may require specialized conveyor systems to prevent spills or sticking to the conveyor belt.

Considerations Regarding Food Conveyors

While food conveyors offer many benefits, there are also some considerations to keep in mind. One of the biggest concerns is maintenance and repair costs, as conveyor systems can be complex and require specialized skills to fix. In addition, food contamination can occur if the conveyor belt is not properly cleaned and sanitized.

Benefits of Food Conveyors

The benefits of using food conveyors outweigh these considerations. Some of the key benefits include:

Increased Efficiency

Conveyor systems can move food products quickly and continuously through a production facility, reducing processing times and increasing overall efficiency.

Improved Product Quality

Food conveyors can be designed to transport food products gently and without damage. This is especially important for delicate food items, such as fresh fruits and vegetables or baked goods. By reducing the amount of manual handling required during the production process, food conveyors can help maintain product quality and reduce waste.

Enhanced Worker Safety

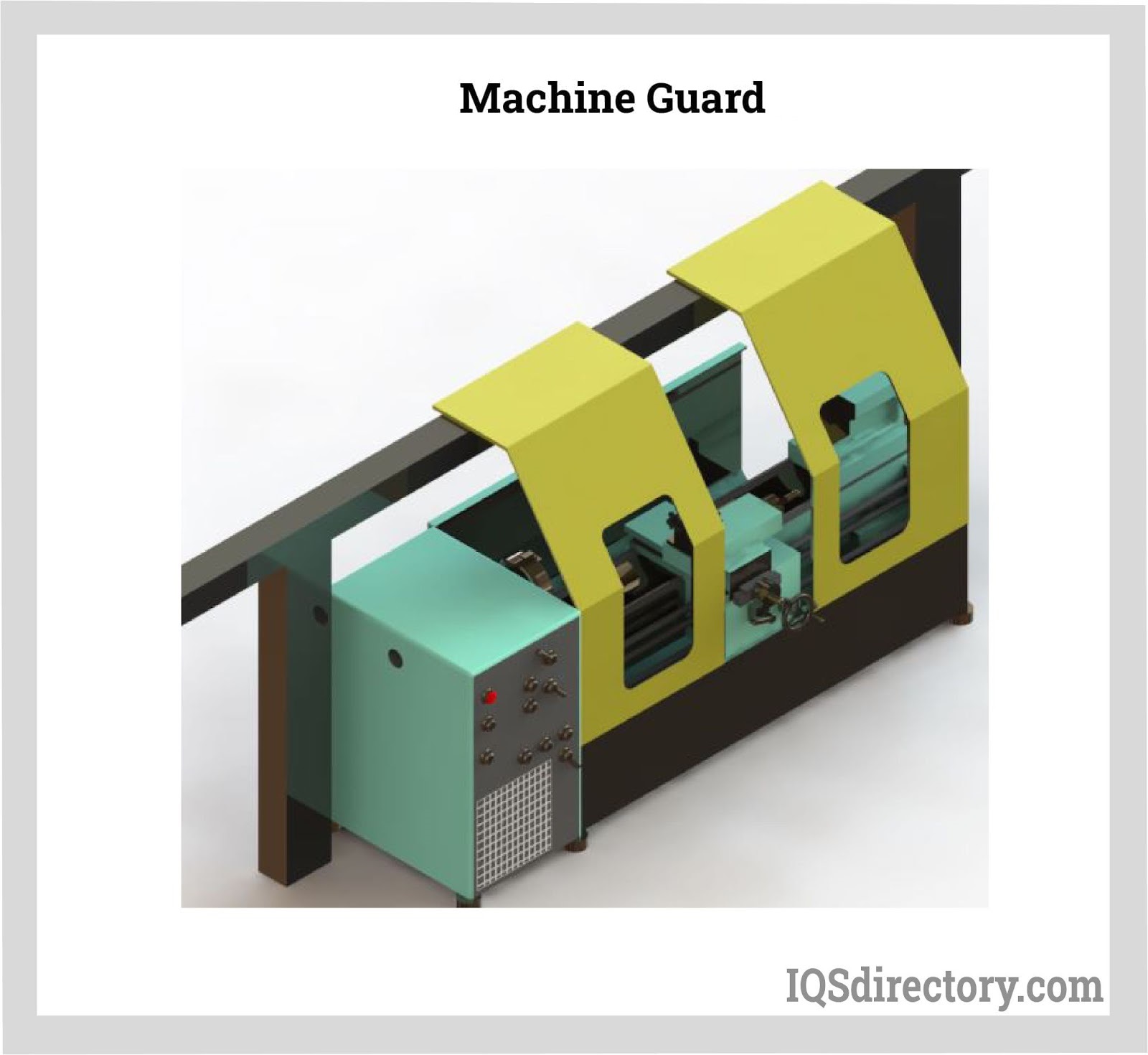

Food conveyors can reduce the need for manual labor in the production process, which can help reduce the risk of worker injuries. Additionally, conveyor systems can be designed with safety features such as emergency stops and safety guards to further enhance worker safety.

Reduced Labor Costs

Conveyor systems can reduce the need for manual labor to transport food products, resulting in reduced labor costs

Applications of Food Conveyors

As a result of these benefits, food conveyors are used in a variety of applications, including:

Bakery Production Lines

Conveyor systems can transport raw ingredients, mixtures, and finished products along the production line in bakeries.

Meat Processing Plants

Conveyor systems can transport raw meat products to different processing areas, such as cutting and packaging.

Bottling and Canning Factories

Conveyor systems can transport empty bottles and cans to the filling area, and then move the filled bottles and cans to the labeling and packaging area.

Choosing the Right Food Conveyor Manufacturer

To ensure you have the most positive outcome when purchasing a food conveyor from a food conveyor manufacturer, it is important to compare several companies using our directory of food conveyor manufacturers. Each food conveyor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each food conveyor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple food conveyor companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

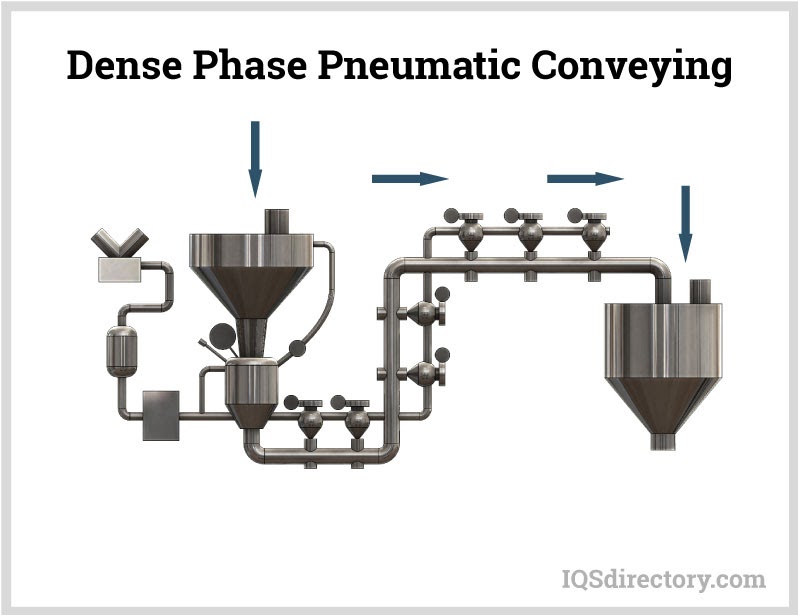

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches